25 Ton Electric Winch for Oil Field Flare Tower Installation

The oilfield flare tower manufacturer in Italy commissioned the design of the explosion-proof electric winch. The purpose of the oil field flare tower is to gather some combustible, explosive, and other harmful gases (mostly methane, ethane, etc.) for burning and consumption during the extraction of oil and gas in order to protect the safety of construction workers.

This time, the Italian client is supplying flare towers for the new oilfield project in Nigeria undertaken by A American Oil Company. On the side of the flare tower, there are some gas guide pipes that need to be installed and maintained, and they call for an explosion-proof electric winch.

oil field flare towe to burn explosive gas

oil filed flare tower assembly drawing by explosion proof winch

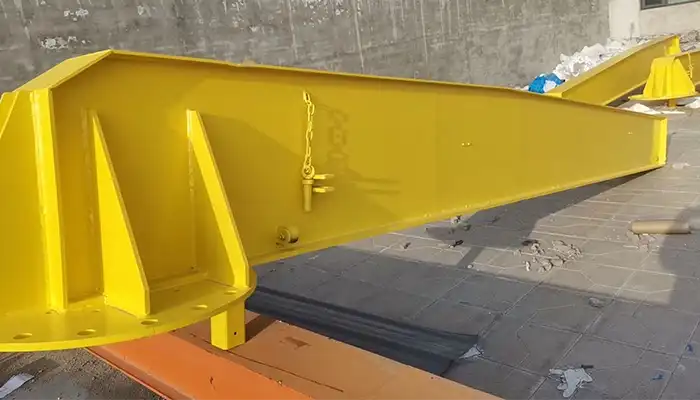

Electric winch for oild field

The flare tower's gas pipe is constructed from a number of separate pipes. A single pipe weighs between 5-8 tons, while the combined weight of all pipes is between 80 and 100 tons. One by one, each pipe must be lifted from the ground and installed.

The lifting procedure for steel pipes is as follows:

- 1. To begin, pull the first section of gas pipeline resting flat from the ground perpendicular to the ground so that it is parallel to the flare tower using an electric winch. The gas pipeline's top serves as the lifting point, and it has a movable pulley for simple rotation. JM10 ton, also known as a flip winch, is the hoisting winch that certain clients use.

- 2. Move the pipe that was hoisted in step 1 to another winch hoist, transfer the weight there, and pull vertically. The electric winch type is JM type electric winch 25 ton , referred to as hoisting winch here.

- 3. Pull down the remaining pipelines on the ground with the turning winch. When the second section of pipeline is in place, it will be rigidly connected to the first section before performing vertical lifting operations with the hoisting hoist.

- 4. Repeat the previous steps until all of the pipes are in place.

Examination of the flip winch pulley

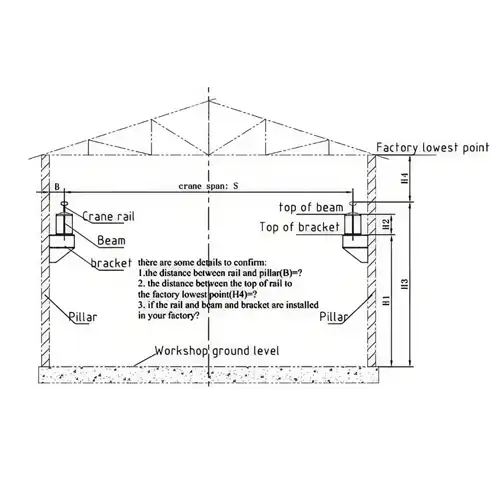

The turning winch (JM10 ton electric winch) is mounted on the ground, and the pulley system is comprised of steering wheels D1, D2, and the movable pulley M1 at the pipe's end.

Vertical hoist pulley analysis

The horizontal lifting winch (JM25T) is mounted on the ground. The pulley system is made up of steering pulley D1, fixed pulley block D3, and movable pulley block M2, with D3 and M2 being three-piece pulley blocks with a 6/1 ratio, so the actual pulling force of the JM25T winch is increased to 1500KN (150 tons) to lift the assembled 100-ton main pipeline.

(The steering wheels marked with red circles in the figure are temporarily ignored to simplify working conditions.)

Pulling of 25 ton electric winch & 10 ton winch

Pulling of 25 ton electric winch & 10 ton winch Wedge sleeves and steel wire anchors

Both the JM10T pull-turn winch and the JM25T vertical lift winch have a single-exit rope, but both have a pulley, so the end of the wire rope must be fixed at an anchor point, as shown in the basket ring on the right.

A set of wedge sleeves is required to secure the anchor point and wire rope, which we also supply. The shaft of the wedge sleeve can be reversed to accommodate the rotation of the wire rope when it is pulled, reducing torsion, increasing wire rope life, and increasing construction safety. As shown in the figure below, the wedge sleeve is imported from the United States, and the shaft and wire rope are treated with glue.

wire rope analysis of electric wire rope winch

wire rope analysis of electric wire rope winch Both explosion proof winches have the following features: 1.ATEX BT3

The electric winches' explosion-proof components are primarily the motor, brake, and electrical box. In the European Union, the explosion-proof level of an electric winch is ATEX. The explosion-proof winch is built with ATEX-certified Siemens motors, Siborui brakes, and Nanyang Zhongtong electric appliances.

explosion proof features of 25 ton electric winch

explosion proof features of 25 ton electric winch The two electric winches' wire ropes have a safety factor of 5, which means that the minimum breaking force is greater than 5 times the rated pulling force. The original steel wire rope is 3-4 times stronger. Solution: replace it with Langshan steel wire rope, which has a tensile strength of 1960 N/mm2 (JM10T) and 2160 N/mm2 (JM25T).

Exporting to Nigeria necessitates PC&SONCAP certificates, and third-party inspection is provided as needed by the client.

Non-destructive testing (NDT) necessitates raw material UT (ultrasonic testing) and weld MT (magnetic particle testing).

wire rope of electric rope winch

wire rope of electric rope winch Contact us to get your customized explosion proof hoist, winch, and exproof crane for oil and gas industry.